|

3.3 Special

Glasses and Coatings

In addition to differences in

magnification and brightness, competing lenses can differ in such

optical qualities as color fidelity,

sharpness, and contrast. The tricks used by lens

designers to manipulate these qualities are worth briefly surveying,

since they give rise to a number of technical terms which have been

appropriated by various marketing strategists hoping to liberate you of

your well-earned cash. (In other words: these things are good to

know when you’re shopping for a birding lens). These design

techniques involve, among other things, the use of higher quality

glass, the optimal placement of those glass elements within the optical

system, and the application of transparent coatings to the lens

surfaces to improve their receptivity to light.

A typical telephoto lens will have anywhere between

10 and 20 glass elements of various shapes and sizes, all arranged in a

precise layout so as to accomplish the lens designer’s goals of

providing a particular combination of focal length, maximum aperture,

and field of view.

Precisely how this all works is complex, and

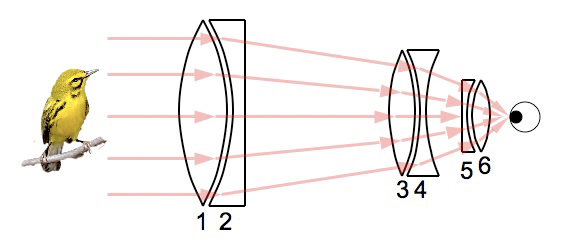

largely irrelevant for our purposes. A simplified block diagram

of a hypothetical telephoto lens is shown in the figure below.

Fig. 3.3.1: A

hypothetical block diagram for a telephoto lens.

Each oval or polygon represents a glass element.

Combinations of elements help to negate the color

dispersion introduced by individual elements.

The important thing to understand is that each lens element bends (or refracts) the incoming light in a

prescribed

way, and that combinations of these lens elements work in tandem so as

to focus all those light rays into the same plane—namely, the plane of the imaging

sensor (represented by the focal point of the eyeball in the figure

above).

The amount of bending that each element applies to

the light depends on the so-called index

of refraction of that element, which is determined by the

optical properties of the type of glass used to make that

element. The problem is that different wavelengths of light

(i.e., different colors) refract at a slightly different angle,

resulting in what is known as dispersion.

Thus, in a single-element lens system like the one shown below, the

different colors (and shades of color) of a bird would be focused onto

different

planes. Since the imaging sensor occupies only one plane, only

one color would be in focus, and everything else would be

blurred. We say that the resulting image suffers from severe chromatic aberration.

Fig. 3.3.2:

Color dispersion in a single-element system.

Different wavelengths of light refract at slightly

different angles, resulting in chromatic aberration.

This is one of the reasons why

camera lenses invariably contain multiple optical elements: so that

downstream elements can act to mitigate, or “clean up” the dispersion problems created

by more upstream elements. Intuitively, you can think of

different elements with opposite dispersion propensities as “cancelling each other out”, so that all the wavelengths are

channeled back into a consistent light path, resulting in a properly

focused image in all color channels. That’s the ideal case.

In reality, most optical systems exhibit at least a small amount of

chromatic aberration. If you’ve ever zoomed way in on an image

(on the computer) and noticed some off-color halos (“color fringing”) around objects, that’s likely

caused by chromatic aberration (though it could also be caused by lens flare or by artifacts in the

digital sensing process).

The problem is that the dispersion properties of “normal” glass are such that crafting a

system of optical elements that collectively result in a sharply

focused image is extremely difficult in practice. One way to make

this easier is to use glass with different dispersive properties than “normal” glass. The Abbe number of a given type of

glass describes these dispersive properties, with higher Abbe numbers

corresponding to lower propensities for dispersion. Using glass

with a high Abbe number will therefore simplify the task of a lens

designer in counterbalancing the various sources of

dispersion, since the dispersion introduced by any single element will

be smaller and therfore easier to correct. Since no lens design

is ever 100% perfect, this means

that lens designs incorporating low-dispersion glass elements should,

as a general rule, suffer less from chromatic aberration. And

that’s a good thing.

There are two popular classes of low-dispersion

glass now in popular use. The first, developed separately by

researchers at Canon and Zeiss in the 1970’s, is known as fluorite and is formed from calcium flouride crystals grown

synthetically in a laboratory. Fluorite elements have excellent

dispersion properties, as well as higher light transmission than

current alternatives (resulting in slightly brighter images).

Unfortunately, fluorite lenses are expensive to produce, for various

technical

reaasons.

The other popular class of low-dispersion materials

is known as ED, or extra-low dispersion glass.

The term is a very general one, admitting any manufacturing process

that results in substantially lower dispersion (i.e., a higher Abbe number) than normal optical

glass (excluding true fluorite elements). Thus, different

manufacturers routinely tout their latest low-dispersion glass as ED, UD (“ultra-low dispersion”), SLD (“super-low dispersion”), HD (“high-definition”), or some other

acronym-of-the-week. The manufacturing processes used for these

various materials are poorly documented and often proprietary, though

some at least involve the doping of normal optical glass with fluoride

ions[1].

What all of these technologies have in common is

that they aim to produce optics which are apochromatic—meaning that they lack (or

minimize) chromatic aberration. A common designation for

apochromatic optics is APO.

Thus, APO, ED, UD, CaF2 (for calcium

fluoride), and many other similar designations all attest to

some

degree of apochromatism

(meaning that they should suffer very little from chromatic

aberration). In practice, this means that these optics should

produce very little color fringing,

or unnatural color separation in images. Knowing how these

various technologies stack up against each other (i.e., which ones are

better than others)

would, unfortunately, require detailed comparisons which in most cases

don’t seem to

have been performed as of yet.

The only really sure bet would be that an

optical system incorporating one or more low-dispersion elements should

(if designed properly) produce better image quality than a comparable

product incorporating

only standard optical glass. Beyond that, the only way to know

which of several optical systems all featuring different varieties of

low-dispersion glass is the best would be to compare the images taken

through those lenses.

While the use of low-dispersion glass aims to reduce

chromatic aberration, the use of transparent coatings on lens surfaces

aims to improve brightness and contrast, by reducing reflection.

Recall that as a ray of light enters a glass element, some of the light

is refracted (bent inward,

while still passing through the glass), while some of it is instead reflected (redirected backward, so

it doesn’t pass through the glass). The portion of incoming light

that is reflected is effectively lost, thereby reducing light

transmission through the lens, and therefore reducing overall

brightness of the image. But because reflection can also happen

on internal surfaces in a

camera lens (i.e., after passing through

a glass element to the far side), reflected rays can also decrease

image contrast, by

contributing to the overall ambient light level (in

a non-informative way) via random scatter. Thus, reducing the

amount of reflection that occurs at glass boundaries is an important

goal in lens design.

This goal is most often addressed by applying one or

more coatings of a transparent solvent to the individual elements in a

camera lens. The precise chemical formulation of these solvents

is often kept secret by the companies that develop them, who give

them names such as “Special T* Coating” and the like, but the basic

principle behind their effectiveness is as follows. Consider the

figure shown below.

Fig. 3.3.3: The

effect of anti-reflective coating.

(A) At each surface, some of the light is refracted (passes through)

and some is reflected, resulting in loss of brightness and contrast.

(B) With an appropriate coating (shown in pink), a secondary

reflection is made, which cancels the first reflection and causes

the canceled energy to be transmitted back through the lens,

improving brightness and contrast.

In part A of this figure (left),

we have a single glass element with a single light ray (drawn in dark

red) entering from the right. Upon striking the outer surface of

the glass element, most of the light ray is bent (refracted) toward the

interior of the glass element (i.e., leftward), while some of the light

is reflected back toward the right. Later, when the light ray is

about to leave the glass element, it again splits into a refracted

portion that continues traveling leftward and a reflected portion that

bounces off toward the right. That reflected portion eventually

reaches the far (right) side of the glass element, where it too is

subject to a splitting event: most of the light ray passes

through to the air bordering the glass on the right, while some of it

reflects back toward the left again.

In a properly focused optical system, many such

light rays (like the dark red one in the image above) originating at

our subject (a bird) would conspire to form an image on the camera’s

sensor plane. In a manner of speaking, these rays carry

information about the image to be formed. Meanwhile, the various

random reflections of these

information-bearing rays would contribute to an overall reduction in

the image contrast, thereby degrading the image quality by making the

bird look less distinct in the image (because the overall information

content has been diluted due to scattering of reflected rays).

Those reflected rays that

escape back out through the lens barrel also contribute to an overall

loss of brightness in the image, and (remembering the material covered

in section 2.5) therefore to an increase in

photon sampling error and

thus pixel noise.

In part B of the above figure, we’ve applied one or

more layers of antireflective coating

to the lens (shown in pink in the figure). Precisely how this

particular medium interacts with incident light at the photon level is

beyond the scope of this discussion, but the overall behavior can be

decomposed into two primary effects, as follows. First, the

coating layer now imposes two surfaces through which the light must

pass: the outer, air-to-coating surface, and the inner,

coating-to-glass surface. At each of these the incident light

again splits into a refracted component and a reflected

component. For a well-chosen coating (i.e., one having an index of refraction intermediate

between that of air and that of the glass), the sum of these two

reflected components will be less than the reflected component that

would result from bare glass alone, so that the overall loss of light

would

be reduced. Second, if the layer of optical coating is of an

appropriate thickness (one quarter the average wavelength of incident

light), the twin reflected rays will be out of phase with one another, and

will therefore cancel each

other out. Because of the (sometimes

counterintuitive) way that light waves work, this cancelation not only

decreases the total amount of reflected light, but actually increases

the amount of light transmitted through the lens[2].

The result is

an increase in both contrast (due to a reduction in stray light from

internal reflections) and brightness (due to increased light

transmission through the glass surface).

Today, most optics from both brand-name and

third-party manufacturers have some sort of antireflection

coating. Many products boast “full multicoating”, meaning that all surfaces of all

glass elements are coated. Products described as “fully multicoated” have mutiple coats applied to

every glass surface in the lens, with different layers formulated so as

to target different wavelengths of light. Keep in mind that while

the improvement in light transmission due to coating on a single lens

surface may be only a few percent, the total improvement resulting from

coating all lens surfaces in a design with 10 or 20 glass elements can

be many times higher, so that today’s high-end optics boast

transmission rates as high as 99.9%[3].

In summary, special glasses such as fluorite (CaF2)

and

ED/UD/SLD/etc. are important for reducing chromatic aberration and

retaining sharpness, with true fluorite elements being the best (and

most expensive) and non-fluorite or semi-fluorite ED variants being

(generally) only slightly less effective (but much cheaper) than

fluorite. Lens coatings are also very important in improving

brightness and decreasing light scatter due to reflection, resulting in

higher contrast images in which the bird and all its details are more

visually distinct.

References for this Section

1. Zeiss Inc.

(2005) Definition

of FL’s. Zeiss Press Release #003/05.

2. J. Petykiewics

(1992) Wave Optics.

Klewer Academic Publishers.

3.

http://www.canon.com/technology/canon_tech/explanation/thin_film.html

|

|

|